When we develop a new designed Bull Bar, whether it be a Kenworth, Volvo, Western Star or any other brand of vehicle, we take everything we have learnt through repairing bull bars of that make and model. We consider the consistent repairs, cracks, and failures. We test the products integrity, along with components to measure the effectiveness or weakness. We consider owner and operator feedback. These are just some of the information we use before we even begin a design, we aim to provide, the best products on the market. How strong is your product? Why not have a look at some of our testing.

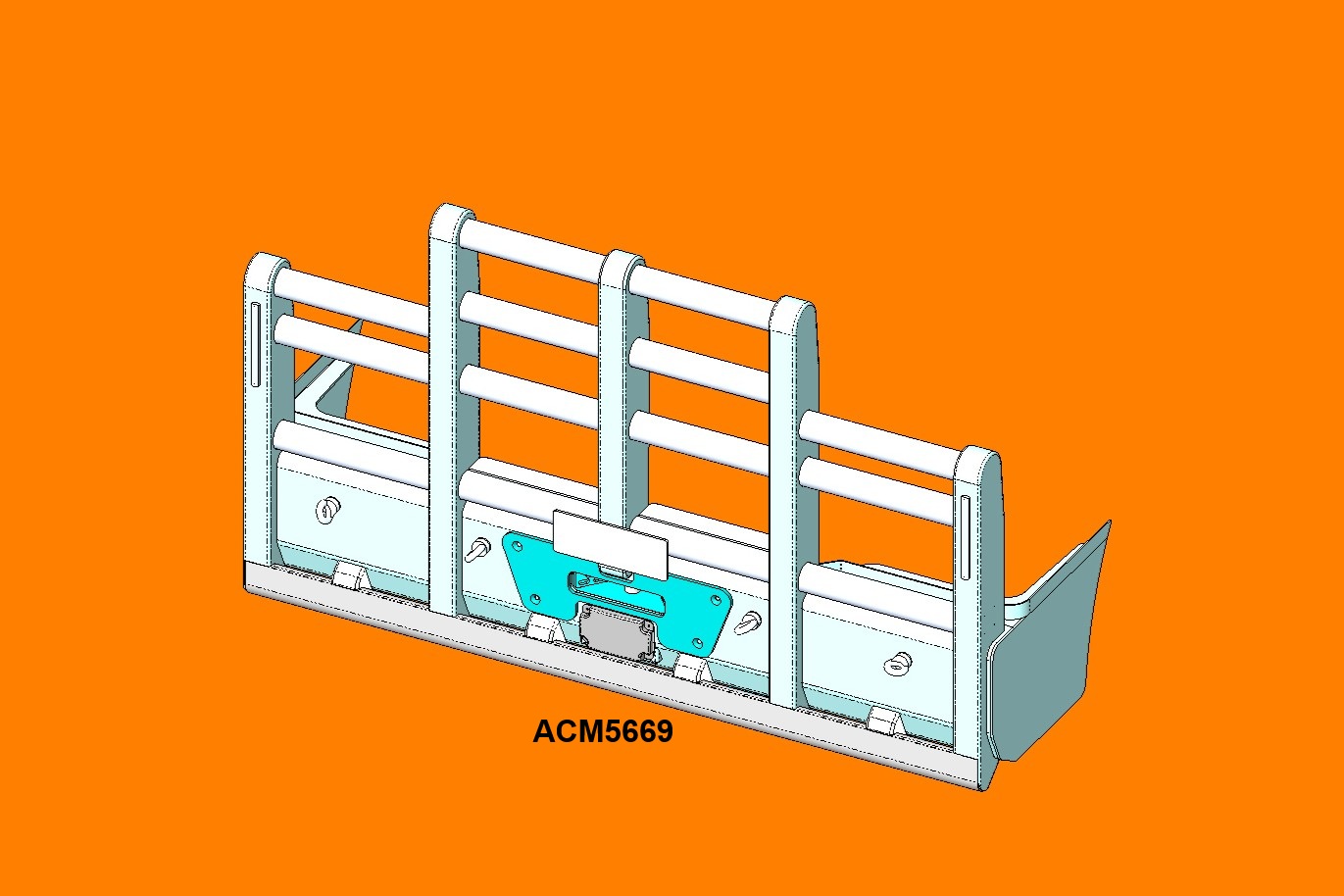

Our products are far from stock-standard. Before a product even reaches the design phase, we account for the exact make and model to ensure that the final product is suitable.

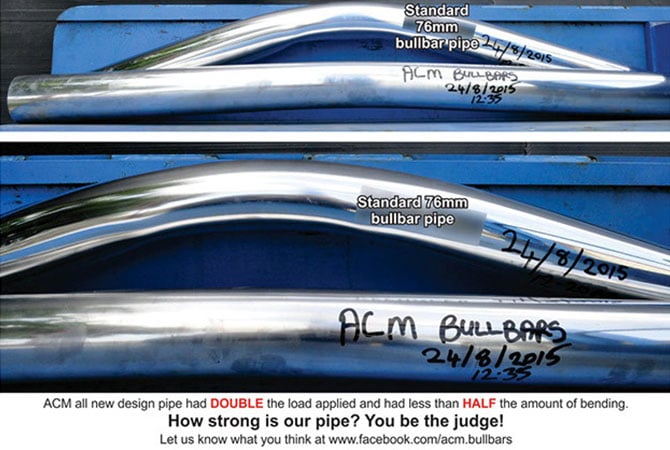

All our bullbars showcase the ACM engineering that’s been setting new industry standards for years. Through extensive testing, we've proven our round pipe bends 80% less under heavy loads compared to conventional pipe. And while some of this is not obvious from the outside, it's certainly proven when an accident occurs.

Other key design features include:

✓ Premium grade aluminium alloy construction

✓ Premium 350 grade steel mountings & brackets

✓ Reinforced mounting points for secure attachment

✓ Aerodynamic design to maintain fuel efficiency

✓ Tailored engineering for all makes & models

✓ FUPS/FUPD compliance where required

Our original V4 FM/FH Bullbar was based on operator feedback from the industry along with our many years of experience. Our round pipes carry double the load of others in the market place and under testing bend less than half of other competitor bullbars. A 20% reduction in the light zone opening has increased its strength, along with a 25% stronger aluminium lights splitters, has seen a dramatic increase in strength and protection of this area, with a stronger overall construction and a steel box section we have been able to provide a heavy duty tow point as standard, with a higher capacity than other products on the market..

During our research ground clearance and approach angles were a major concern to operators. Our design has been able to maximise the approach angles eliminating current problems with competitor bars that bottom out or scrap upon entering uneven driveways and other off road applications

A lot of European vehicles are designed closer to the ground, enabling safer entry, and many other benefits. While this can be an advantage we have found that approach angles are compromised once a bullbar is fitted. Our design is based on operator feedback, with approach angles being a concern for those vehicles constantly negotiating steep entrances and off road applications. Taking this on board we have designed the bullbars for maximum clearance.

As part of our development and research, we already knew what was failing in the market place due to us continually repairing other brands of bullbars out there in the market place. By starting from a blank canvas we were able to design a bullbar and components, from not only many years of experience, but from an operators point of view in what they wanted and required, from the product.

Attached is a PDF click on it to open it and see some of the tests carried out. It certainly begs the question “HOW STRONG IS YOUR PIPE? YOU BE THE JUDGE"

✓ Australian owned and operated

✓ Designs customised specifically for local road conditions

✓ Direct operator feedback and user-friendly features

✓ Balanced approach to strength, safety, performance, and aesthetics

✓ Nationwide service network coverage

✓ Sleek looking bars that shine!